Discovering the World of Stainless Steel Valves and Fittings

In the modern industrial landscape, stainless steel valves and fittings play a critical role in numerous applications. From construction to manufacturing, the reliability and efficiency of these components cannot be overstated. In this comprehensive article, we will dive deep into what stainless steel valves and fittings are, their benefits, various types, applications, and why you should choose products from fitsch.cn for your needs.

Understanding Stainless Steel Valves and Fittings

Stainless steel valves and fittings are essential components used in different systems to control the flow of liquids and gases. Made from high-quality stainless steel, these components offer durability, resistance to corrosion, and a long lifespan. Let’s dissect these components into two crucial categories:

1. Stainless Steel Valves

Valves are mechanical devices that regulate the flow of fluids by opening, closing, or partially obstructing passageways in pipes. The main types of stainless steel valves include:

- Ball Valves: Known for their quick operation and ability to handle high pressure, ball valves provide a tight seal and are ideal for shut-off applications.

- Gate Valves: These valves are used to start or stop the flow. They are not suitable for throttling flow and are perfect for systems that require minimal pressure drop.

- Check Valves: This type allows fluid to flow in one direction only, preventing backflow and protecting equipment from damage.

- Butterfly Valves: Often used for throttling flow, butterfly valves provide a compact solution for larger pipes.

2. Stainless Steel Fittings

Fittings are accessories that connect different pipe sections, allowing for directional changes, branching, and transitions in systems. The common types of stainless steel fittings include:

- Elbows: Used to change the direction of flow, elbows are available in various angles, typically 90° or 45°.

- Tees: This fitting connects three sections of pipe, allowing for a branch in the flow.

- Reducers: These fittings are used to connect pipes of different diameters, ensuring a smooth and efficient flow transition.

- Flanges: Flanges connect pipe sections or components. They offer a sturdy and leak-proof connection.

Benefits of Using Stainless Steel Valves and Fittings

The implementation of stainless steel valves and fittings in industrial applications brings numerous advantages:

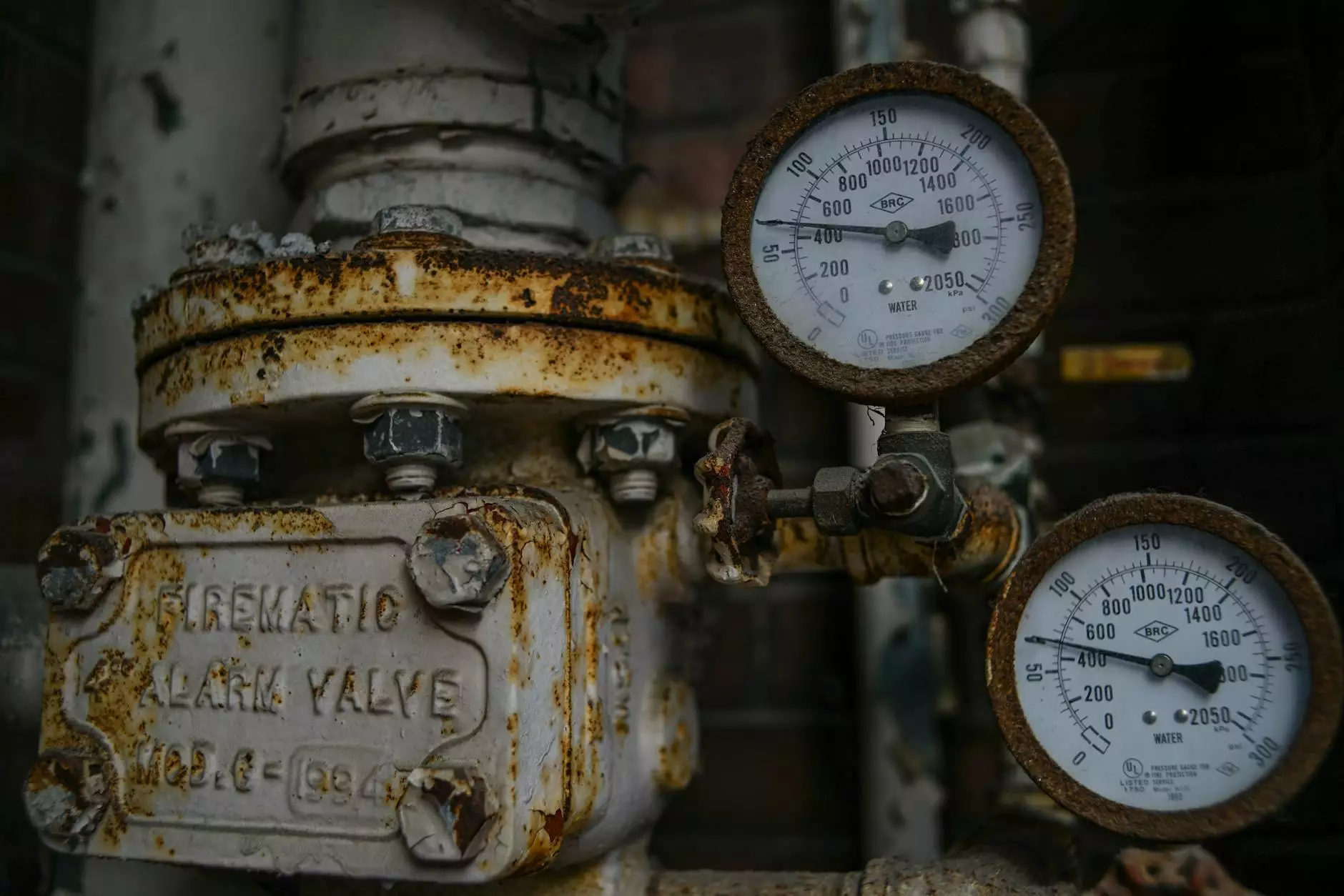

1. Corrosion Resistance

Stainless steel is inherently resistant to rust and corrosion, making it suitable for environments exposed to moisture or corrosive substances. This quality enhances longevity and reduces maintenance costs.

2. Strength and Durability

These components are designed to withstand high pressures and extreme temperatures, ensuring dependable performance in demanding applications.

3. Hygiene and Safety

Stainless steel is non-porous and easy to clean, making it an excellent choice for industries such as food and beverage, pharmaceuticals, and water treatment, where hygiene is paramount.

4. Versatility

Stainless steel valves and fittings can be utilized in a wide range of applications, from residential plumbing to aerospace, making them highly versatile components.

5. Economic Viability

While the initial investment may be higher compared to other materials, the durability and low maintenance needs lead to long-term savings, making stainless steel an economically viable option.

Applications of Stainless Steel Valves and Fittings

Stainless steel valves and fittings are ubiquitous across many industries. Here are some critical applications:

1. Oil and Gas Industry

In the oil and gas sector, these components are crucial for controlling the flow of fluids under high pressure. Their durability ensures safety and efficiency in operations.

2. Water Treatment Plants

For water treatment, stainless steel valves and fittings help in managing the flow of water, including drinking water systems, waste management, and wastewater treatment.

3. Food and Beverage Industry

The hygienic properties of stainless steel make it indispensable in the food and beverage industry, where cleanliness and compliance with health regulations are vital.

4. Chemical Processing

Stainless steel valves and fittings can withstand corrosive chemicals, making them ideal for the chemical processing industry, where such robustness is essential for safety and reliability.

5. Pharmaceutical Industry

The pharmaceutical industry requires strict adherence to hygiene standards, making stainless steel an ideal material choice for valves and fittings used in the production and packaging of medications.

How to Choose the Right Stainless Steel Valves and Fittings

Selecting the appropriate stainless steel valves and fittings involves several considerations:

1. Material Grade

Different grades of stainless steel offer varying levels of corrosion resistance and strength. Ensure the chosen material suits your specific application.

2. Pressure Rating

Consider the maximum pressure that the valves and fittings will encounter in your application, and ensure they meet or exceed these requirements.

3. Size and Compatibility

Ensure compatibility with existing systems by checking the size and type of fittings, as this can influence installation and performance.

4. Regulatory Compliance

Verify that the valves and fittings meet relevant industry standards and regulations, especially for applications in sensitive fields like food or pharmaceuticals.

Fitsch.cn: Your Destination for High-Quality Stainless Steel Valves and Fittings

At fitsch.cn, you’ll find a comprehensive range of stainless steel valves and fittings tailored to meet your specific needs. With our commitment to quality and customer satisfaction, we ensure that all our products deliver optimal performance in every application.

Why Choose Fitsch.cn?

- Wide Selection: We offer a vast range of products, including various types of valves and fittings.

- Quality Assurance: Our products go through rigorous testing to ensure they meet the highest standards.

- Competitive Pricing: Get the best value for your investment without compromising on quality.

- Expert Support: Our knowledgeable team is ready to assist you with any inquiries or support you need.

The Future of Stainless Steel Valves and Fittings

As industries evolve and technology advances, the demand for high-performance stainless steel valves and fittings will continue to grow. Innovations in materials, design, and manufacturing processes are creating even more efficient solutions for controlling fluid flow.

At the forefront of these advancements, fitsch.cn is dedicated to providing state-of-the-art products and maintaining exceptional standards in quality and service, ensuring our customers have access to the best solutions for their needs.

Conclusion

In conclusion, stainless steel valves and fittings are indispensable components within various industries, providing essential functions such as flow regulation, safety, and efficiency. Their durability, corrosion resistance, and versatility make them an ideal choice for many applications. Investing in high-quality valves and fittings from fitsch.cn ensures that you are choosing longevity and reliability for your projects.

Make the right choice for your industrial needs today and experience the benefits of using stainless steel products!